Underutilized switchers can drain budgets in news studios. Learn how software-defined platforms cut idle power, free rack space, and turn sunk gear into ROI.

Is that massive production switcher servicing your news control room, providing the best value for your budget?

In too many facilities, production switchers run up the electric bills 24/7 but are of limited value outside of the news broadcast windows. Sill, that idle capacity has long been the cost of ensuring systems are available during those precious peak revenue hours when the news is live.

Until now.

The fact is, underutilized equipment limits creativity, ties up engineering resources, and has a direct impact on the bottom line. A strategic software-defined workflow can provide greater efficiency at a lower total cost of ownership.

Modern broadcast demands vs. legacy hardware constraints

Many legacy switchers were built for a world where HD was the gold standard and news broadcasts followed a predictable format. In that world, those systems performed well because production demands were consistent and relatively straightforward. But as the number of news outlets has exploded and the demand for 24/7 news has grown, the need to provide compelling visual content across multiple platforms and locations is now paramount in the battle for viewers.

Fixed hardware systems often can’t deliver the necessary production horsepower, so broadcast news facilities are forced to make difficult choices: Cut creative content or deploy additional, often redundant, hardware that increases complexity and drives up costs, but sits idle during non-peak periods.

The result?

Facilities must invest in expensive equipment that sits idle for most of the week, waiting for the next big story. This mismatch between static infrastructure and dynamic production has become the root cause of widespread underutilization, and a growing pain point for broadcasters trying to stay competitive in a fast-paced, multi-platform world.

The hidden costs of idle equipment

On the balance sheet, a switcher looks like a single line of capital expense. On the production floor, it’s an ongoing tab. When that box sits unused for more than half of the broadcast day, it becomes an expensive luxury. It continues to burn power, it still requires cooling and maintenance, and depreciation keeps grinding away whether the “On Air” light is on or not. The extra capacity needed to cover peak periods, which might only last a few hours a week or just a few months a year, ties up cash that could fund new content or more staff.

And the consequence isn’t just financial. A rigid, under-utilized news control room also impacts creative decisions. Maybe there’s not enough I/O for an extra remote, or there’s not enough keyers for that one additional graphic, simply because the switcher’s resources are fixed and inflexible.

The consequences of underutilized hardware are costly and complex:

- CapEx burn: Every underused board represents capital that could be put to better use.

- Diluted ROI: Buying extra switchers for limited spikes lowers the return on all installed gear.

- Higher TCO: Switchers run 24/7, racking up electricity, cooling, and maintenance costs even while idle.

- Hardware duplication: Covering peak demand with legacy systems means duplicate frame and panels, additional licenses, and more staff retraining.

- Missed opportunities: In remote or centralized models, you can’t spin up extra capacity fast enough to chase breaking stories.

Taken together, these costs create an invisible drain on every production. Why does this problem feel bigger every year? Content formats keep multiplying, live events keep expanding, and remote workflows push resources to their limits.

Inside the Austin Media Center

In this exclusive on-demand webinar, hosted by TV Tech, you’ll hear first hand from the leaders behind the build, as they share the planning, technology decisions, and lessons learned during a multi-year, multi-phase project.

Why the problem is getting worse

Just a decade ago, one operator on one switcher could punch out two linear shows per shift and call it a win. Today, that same operator, using the same switcher, is asked to send feeds to multiple destinations, each in a different format, and each with its own creative and technical requirement.

In this landscape, that explosion of outputs turns any extra headroom into a shortfall. Switchers designed for a single HD path can struggle to adapt when productions require alternative formats, such as archiving in UHD, while down-converting the broadcast to HD. While most broadcasters still operate in a single format at a time, the ability to quickly reconfigure between formats without major hardware changes offers a significant advantage.

Meanwhile, production is becoming increasingly decoupled from geography. Remote workflows enable crews to produce shows from thousands of miles away, and while not all remote setups require it, the ability to share resources on demand dramatically increases flexibility and efficiency. Parking a fully loaded switcher in one studio while another show across town, or across the continent, hunts for additional resources no longer makes sense.

Add in today’s economic backdrop of higher energy prices, squeezed CapEx, and aggressive sustainability targets, every idle watt becomes a missed opportunity. To stay ahead, broadcasters are under pressure to shrink racks, cut power, and prove that they are getting the most out of their gear.

In other words, the cost of underutilization isn’t just rising. It’s compounding.

The solution? Software-defined hardware.

Why a software-defined solution is the future of broadcast

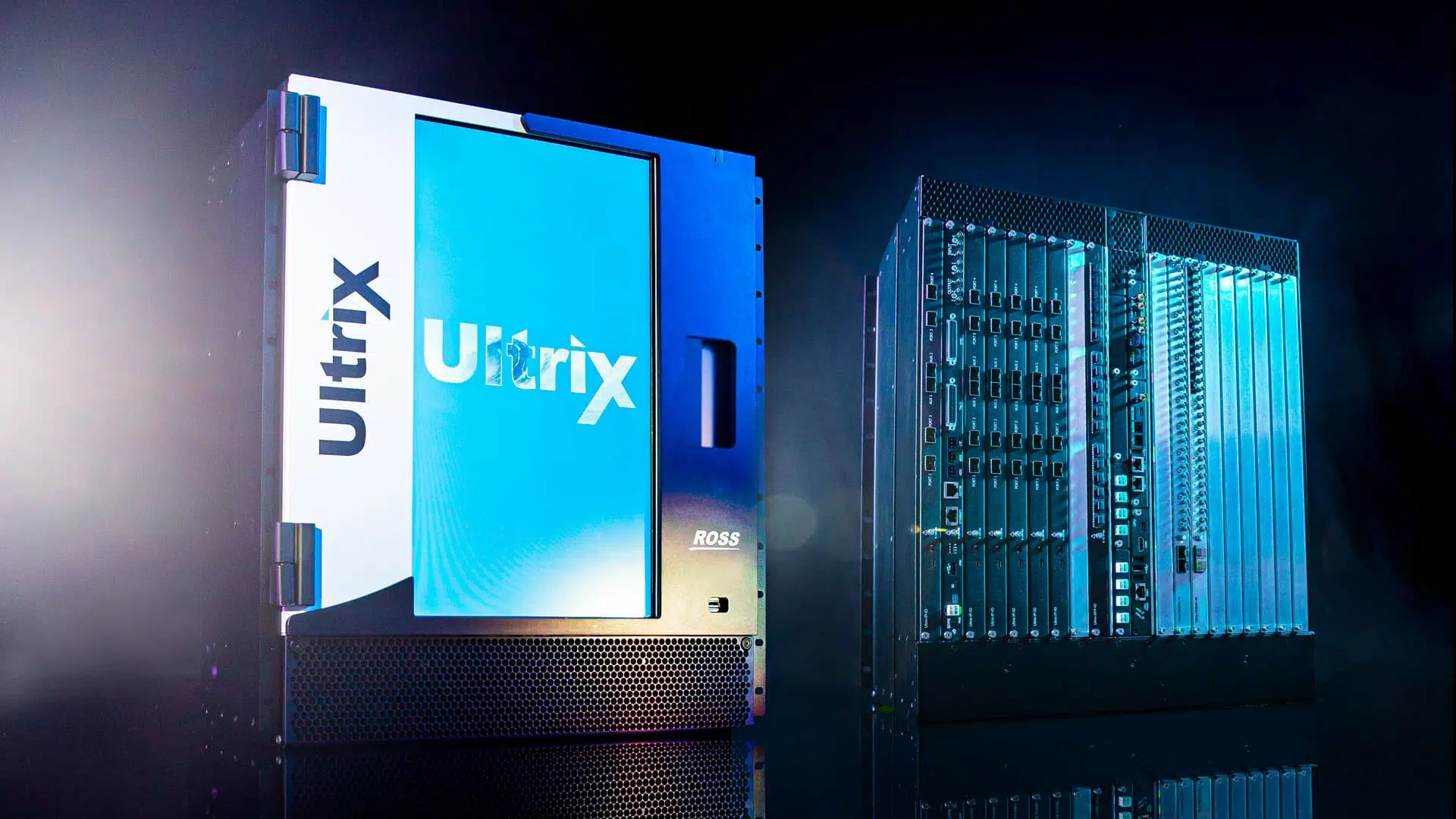

Swapping out purpose-built hardware for a software-defined, hyperconverged platform addresses every pain point we’ve covered so far. Instead of single-purpose frames for the switcher, router, multiviewers, format converters, and audio embedders and de-embedders, hyperconverged systems consolidate all those functions through software-defined blades.

The operation of each blade depends on the license that is loaded. Need another ME with DVEs for a graphics-heavy segment? Deploy the license and poof! Another ME bank. When the show ends, reassign that same blade to another switcher – no repatching required.

Because resources are defined by software licenses, scaling up no longer means stacking duplicate boxes. Add a new blade, activate the right license, and instantly shift from running multiple independent switchers to pooling resources into one larger switcher, all within the same frame. Operators keep the panels they know, and engineering teams manage everything from a browser, shifting licenses across rooms — or continents — in minutes.

In practice, the platform feels less like a traditional switcher and more like a pool of production horsepower you can allocate on demand.

Here’s how software-defined production can provide immense cost savings:

- Increased Utilization – When one show ends, the idle ME resources can be instantly assigned to a different show, maximizing the efficiency of every component

- Reducing Hardware Duplication – Since existing licenses can be reallocated as needed, covering peak periods no longer requires additional fixed-use hardware.

- Future-Ready Features – Add support for new formats or workflows by updating firmware or licenses, practically eliminating forklift upgrades.

- Comprehensive System-Wide Control – Browser-based management lets engineers reallocate resources from home base, a perfect solution for REMI or hybrid Cloud workflows.

What makes today’s software-defined platforms especially compelling is their all-format DNA: SDI, SMPTE 2110, NDI, even HDMI and fiber can mingle in the same frame, so legacy paths and IP pipelines coexist without bolt-on gear. Enterprise control layers provide a single dashboard for licensing, monitoring, and failover—turning what used to be a rack of “single-points-of-failure” into a shared, self-healing resource pool.

Yesterday’s single-purpose hardware mode asked: How much more money will it cost to achieve your goal?

Tomorrow’s software-defined hardware solution asks: How do you want to use the power and capability you already own?

That shift—from capital-heavy silos to an agile, license-based ecosystem—is why software-defined production is quickly becoming the new normal for multi-room news studios.

Maximize your hardware investment by minimizing underutilization

Underutilized switchers and processors levy an unseen tax on your business, as they consume capital, occupy scarce rack space, drive up electricity bills, and increase staff costs, all while sitting idle for a considerable portion of their useful lives.

Software-defined, license-based hardware flips the script. Instead of locking horsepower into single-purpose frames, it can be allocated and reallocated as needed – whether it’s consolidating ME banks into one large switcher for the morning show or separating them afterward for multiple smaller productions – increasing utilization and stretching CapEx dollars. Scaling becomes a click, not a forklift.